WAS ambulances: From manufacturing to configuration

From manufaturing to configuration – is that really possible? How Wietmarscher Ambulanz- und Sonderfahrzeuge GmbH (WAS in short) answered this question and how the team around Product Managers Ulrich Konitzer and Andreas Fafenrot came to implement it in short period of time, they tell us in this interview with Sandra Szech.

WAS is a leading manufacturer of ambulances and special vehicles. Vehicles for customers all over the world are manufactured at the plant in Wietmarschen to meet their individual wishes and specific requirements in the best possible way.

When we met about a year and a half ago, you were facing a major challenge: moving from manufacturing to configuration. What was the deciding factor back then for you to actually make the change?

Andreas Fafenrot: As a company, we strive to be successful – to optimize production, to bring more vehicles into the field and to continuously expand our customer base. However, we have realized that it is mainly the variety of customer requirements that poses challenges for us.

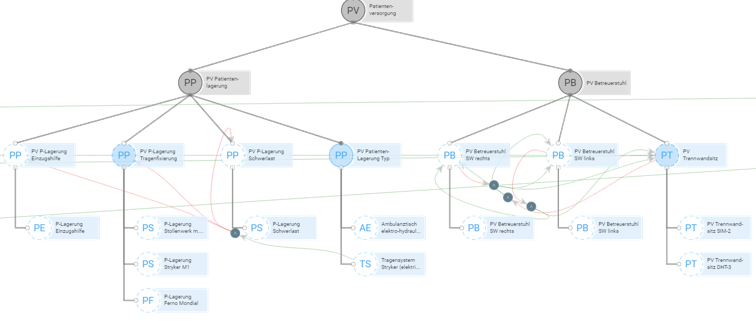

Ulrich Konitzer: Every day, we created new variants that we were unable to master in terms of construction, security and production. The dependencies were constantly becoming a greater challenge, everything was becoming more and more complex. One of the reasons for this is the market: even the basis of the basic vehicle models that we customize has grown immensely in recent years.

And how did you discover that modularization is a key issue for you?

Ulrich Konitzer: When I went through our production facilities, I kept asking myself: why is the implementation one way in one place and completely different in another? The same functions were solved differently, e.g. through different assembly solutions. This is not a requirement from a customer. Why are we doing this and what is the solution? That’s when the idea of modularization emerges.

Today you are a whole step further. The modular system is ready, the configurator is being set up and the organization is being changed accordingly. What were your success factors that enabled you to take the decisive steps in such a short time?

Ulrich Konitzer: It was a great challenge for us to take staff away from the specialized departments in order to devote a large part of our time to the task of modularization. We went so far as to oursource the technical design.

Andreas Fafenrot: This was only possible because we combined the upcoming product revisions with the modularization. In order to achive implementation as quickly as possible, we defined standardization for the specialists and technicians. Standardization made it possible to build up specialized knownledge, which is the basic idea and theory behind the modular system. Thanks to the guidelines, we were able to involve a large group of people in the implementation. Odego Cquenz has enabled us to achieve standardization and modularization.

Ulrich Konitzer: Limiting the variance and reducing the dependencies would not have been possible in this form without the tools and the support of Odego. Not only to invole people from outside. I’ve been involved for many years, but I was able to expand my knowledge of the variety and its effects in the vehicle.

Andreas Fafenrot: Yes, that’s how we achieved precision and structure. In Cquenz, we have streamlined the products. Which variants are needed and which are unnecessary? Where does the variance lead to problems and where does it not? With these findings, it was possible to define concrete specifications for implementation by our external partners.

Ulrich Konitzer: That went all the way to implementation in the configurator. The partner who set up the configurator with us said that he had rarely seen such a well-prepared model.

What presented you with unexpected challenges?

Andreas Fafenrot: During this change, it is challenging to always get everyone on board at the same time. The change in the standardization process has triggered many discussions, devisions made require repeated explanations and an understanding of different points of view.

Ulrich Konitzer: It was clear to us from the beginning that this would happen. For example, contacts from Odego’s customer network also warned us about this. But it still took more effort than we had perhaps expected. We had to promote the new approach internally, and Odego helped us to explain the modular system internally, take feedback from colleagues and also convince the “critics”.

Andreas Fafenrot: In the beginning, the approach is still very abstract for the entire organization. Many colleagues only realize what it really means when it is put into practice. What helps us is a mutual exchange at fixed intervals throughout the entire process.

What advice can you give to other companies that may be at a similar point as you were 2 years ago?

Ulrich Konitzer: I asked myself at the beginning: Is that really possible? Can our product really be modularized? And now I would say that practically any product can be. In my opinion, only large companies that bring in experts can do this on their own. It worked for us because with Odego we have a partner at our side who eliminates “operational blindness”, looks at it from a different perspective, builds a model and knows how to implement something like this. Without this external support, it is difficult to realize this successfully. And: the team must have the ambition and be motivated.

Andreas: Fafenrot: It was actually clear to me that it was possible because I had already experienced it in my professional career. Nevertheless, the unbelievable number of articles made me doubt it. A diffuse and detached variety. We had tens of thousands of articles in 48 x 1038 possible combinations – at this point, the data analysis provided useful preliminary work. Showing this with Odego Analytics and recognizing the customers’ usage patterns behind it – that gave me the confidence that we could create equipment variants. And that we can provide sales with a product that allows us to offer our customers the individuality they need in an ambulance. Subsequently, we have developed the configuration model in Cquenz. This will probably always be the step to success: breaking down the product in Cquenz to such an extent that you gain deep and comprehensive knowledge about your product. This is the solution path into the configurator, into procurement and production. For me, the key moment was when we completed the configuration model in Cquenz. That’s when I realized that this is definitely feasible and can be implemented.

Thank you very much, Ulrich and Andreas, for these insights into your key experiences and for allowing us to be part of this success story.